The innovation of 3D printing has revolutionized how ideas become reality. Whether crafting replacement parts, designing intricate models, or building prototypes, this technology empowers creators in incredible ways. But for beginners and seasoned users alike, understanding the foundation is essential. At the heart of this transformation lies the need to grasp the fundamentals of a 3d printer and how it works —a step that helps ensure smoother, more successful printing experiences.

The Core Process: Layer by Layer Creation

At its core, a 3D printer works by creating objects layer by layer based on a digital design. This method is called additive manufacturing. It begins with a 3D model, typically designed using CAD (computer-aided design) software. The model is then sliced into hundreds or thousands of thin layers by slicing software.

The printer’s nozzle, also known as the extruder, follows this sliced path and deposits the printing material—usually thermoplastic filament like PLA or ABS—layer by layer until the object is fully formed. Each layer fuses to the previous one with precision and accuracy, eventually creating a solid 3D object.

Types of 3D Printers: Choosing the Right One

Not all 3D printers function the same way. Several types cater to different applications and skill levels:

- Fused Deposition Modeling (FDM): Most common and beginner-friendly. It melts plastic filament to create layers.

- Stereolithography (SLA):Uses UV light to cure resin layer by layer. Ideal for high-detail prints.

- Selective Laser Sintering (SLS): Uses a laser to fuse powdered materials. Commonly used in industrial applications.

Each type has its pros and cons, so knowing your project requirements is essential when selecting a machine. Doing some research or seeking 3d printer advice from experienced users can be extremely helpful.

Materials Matter: What You Use Affects the Outcome

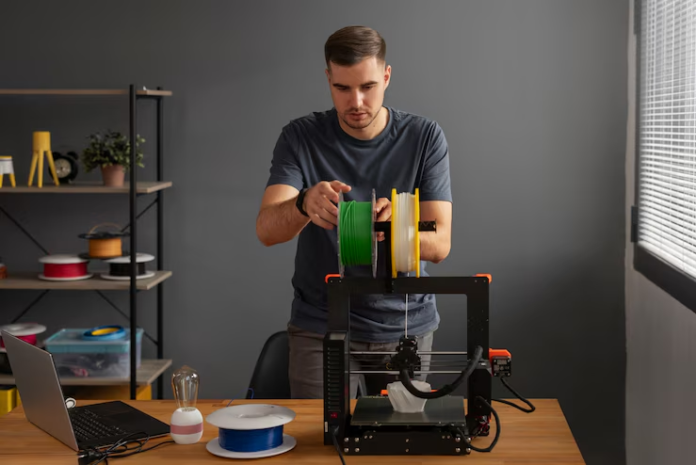

The material used in 3D printing has a significant impact on the final product’s strength, flexibility, and finish. Common materials include PLA (easy to use and biodegradable), ABS (durable and heat-resistant), PETG (strong and flexible), and resins for SLA printers.

Each material has different printing temperatures and bed adhesion needs. Proper storage is also crucial—filaments absorb moisture from the air, which can ruin a print. Using sealed containers or dry boxes helps maintain filament quality and consistency.

Why It Matters: Benefits of Understanding the Basics

Understanding the basics of how a 3D printer works isn’t just for engineers. It empowers hobbyists, designers, educators, and entrepreneurs to:

- Troubleshoot issues more effectively

- Maximize print quality and material efficiency

- Experiment with creative designs

- Make informed equipment and material choices

Without a strong foundation, users may face frustrating print failures, wasted material, and damaged equipment. A little time spent learning the essentials goes a long way in saving time, money, and effort down the line.

Conclusion: Connect with a Community that Supports Your Journey

Whether you’re just beginning or looking to refine your skills, tapping into a supportive community makes all the difference. That’s where 3DPrintingSpace.com comes in. As one of the world’s most vibrant 3D printing forums, it offers free technical support, beginner-friendly advice, and expert insights. From understanding the basics of a 3d printer and how it works to advanced troubleshooting, this platform connects makers from all backgrounds. Explore helpful discussions, share experiences, and get 3d printer advice that elevates your 3D printing journey—all in one place.